Recommended Reading

How the Eight-Point Regulation Changed China

2025-05-16

Sinoma High-Tech Nitride Ceramics Co., Ltd. participated in 2023 Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition.

Time:

2023-09-05

Source:

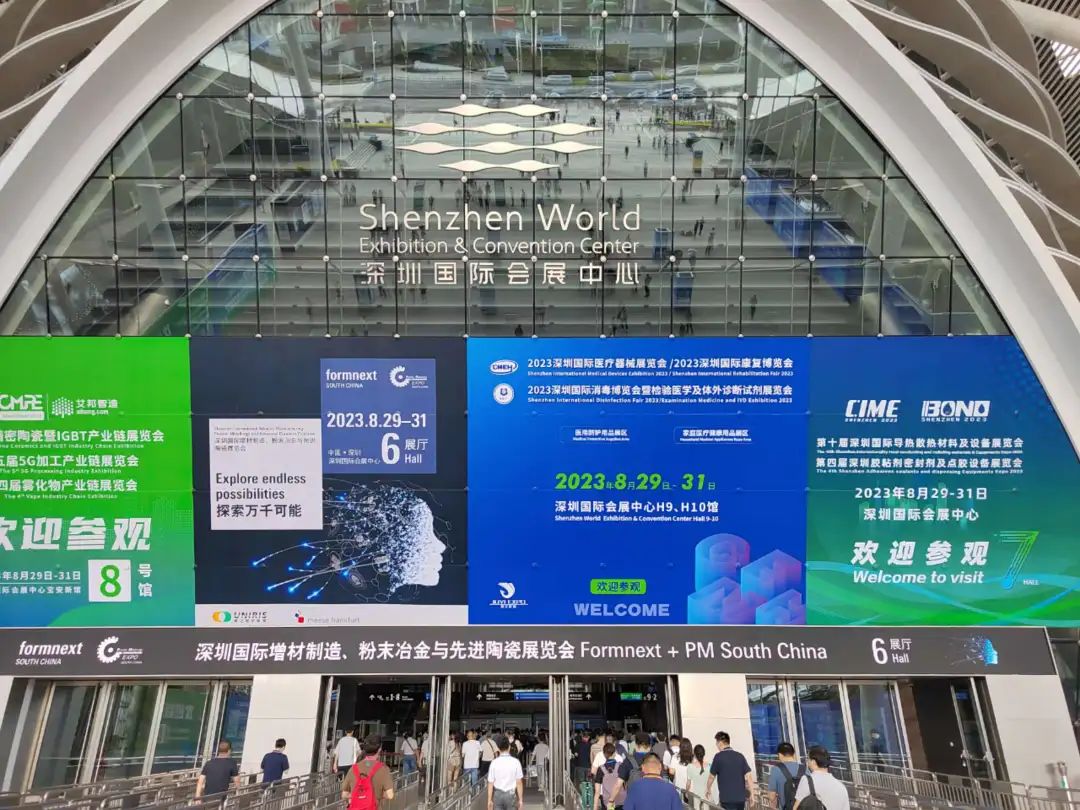

August 29, 2023 Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition (Formnext + PM South China) kicked off, the exhibition focuses on additive manufacturing, powder metallurgy and advanced ceramics related to cutting-edge molding and manufacturing technology, is committed to the industry to capture the market's new dynamics, and to broaden the future map of high-end manufacturing.

August 29, 2023 Shenzhen International Additive Manufacturing, Powder Metallurgy and Advanced Ceramics Exhibition (Formnext + PM South China) kicked off, the exhibition focuses on additive manufacturing, powder metallurgy and advanced ceramics related to cutting-edge molding and manufacturing technology, is committed to the industry to capture the market's new dynamics, and to broaden the future map of high-end manufacturing.

Sinoma Hi-Tech Nitride Ceramics Co., Ltd. made a stunning appearance with its main products, and received more than a hundred leaders, guests and businessmen at all levels every day during the exhibition, with remarkable publicity and promotion effect.

Our company displayed "Hot Isostatic Silicon Nitride Ceramic Balls", "High Thermal Conductivity Silicon Nitride Ceramic Substrate", "High Precision Silicon Nitride Ceramic Structural Components" and other products to the audience, so that more people can understand the excellent performance and application fields of silicon nitride ceramic materials and develop business opportunities. The excellent performance and application fields of silicon nitride ceramic materials, open up business opportunities, for the high-quality development of enterprises to build up momentum and empowerment.

The size of our hot isostatic silicon nitride ceramic ball covers from 0.1mm to 110mm, and the application areas include dental drill bearings of about 1mm, insulated bearings for new energy automobile motors and machine tool bearings of about 10mm, and wind power bearings of about 50.8mm. The product features are a combination of lightweight, wear-resistant, high-strength, self-lubricating, electric insulation and so on. They show outstanding reliability and safety in applications requiring high speed, maintenance-free, and corrosion-resistant environments.

The size of the high thermal conductivity silicon nitride ceramic substrate developed by our company can be customized according to the customer's needs. The special formula and process are used to make the thermal conductivity of silicon nitride ceramic >80W/(m*k) or more. The products are characterized by electrical insulation, high thermal conductivity, low dielectric loss, high strength, etc. They are suitable for third-generation semiconductor devices with high heat generation, such as IGBT, MOSFET, etc., and can play a good role in heat dissipation and encapsulation.

The application areas of high precision silicon nitride ceramic structural parts include polysilicon reduction furnace, low pressure aluminum casting, paper industry and so on. The products have high density, high strength, superior insulation, thermal shock resistance and corrosion resistance, good thermal conductivity and other characteristics, and long product life.

During the exhibition, our booth attracted a lot of attention, guests have stopped to watch, a detailed understanding of the characteristics and applications of silicon nitride ceramic products, and at the same time to communicate and discuss, cooperation and negotiation.

Advanced ceramics is the most promising "track" in the field of new materials, the key technology for the future development of intelligent manufacturing, has become a gas pedal of manufacturing development, is constantly changing the traditional manufacturing methods, and boosting various industries to high-end, intelligent. Sinoma Hi-Tech Nitride Ceramics Co., Ltd. as a deep cultivator in the field of advanced ceramics for more than 40 years, will continue to maintain the pace of innovation, and continue to provide innovative value for China's "smart" manufacturing.