Silicon Nitride Ceramic Balls

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings around 1mm; insulated bearings for new energy automobile motors and spindle bearings for machine tools around 10mm; insulated bearings for wind power generation around 50.8mm, etc.

Keywords:

Category:

Rolling Element

E-mail:

Silicon Nitride Ceramic Balls

High performance hot isostatic pressing (HIP) silicon nitride ceramic balls:

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings around 1mm; insulated bearings for new energy automobile motors and spindle bearings for machine tools around 10mm; insulated bearings for wind power generation around 50.8mm, etc.

Product features: lightweight, wear-resistant, long life, high strength, self-lubricating, electric insulation, etc., in the need for high speed, maintenance-free, anti-electrical corrosion and other application environments play an outstanding reliability and safety.

Previous Page

Next Page

Previous Page

Silicon Nitride Ceramic Balls

Next Page

Related Products

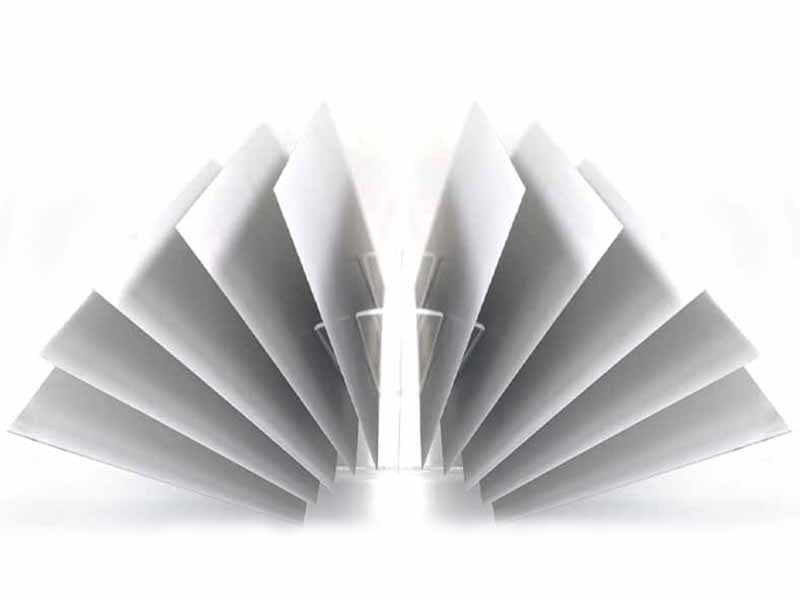

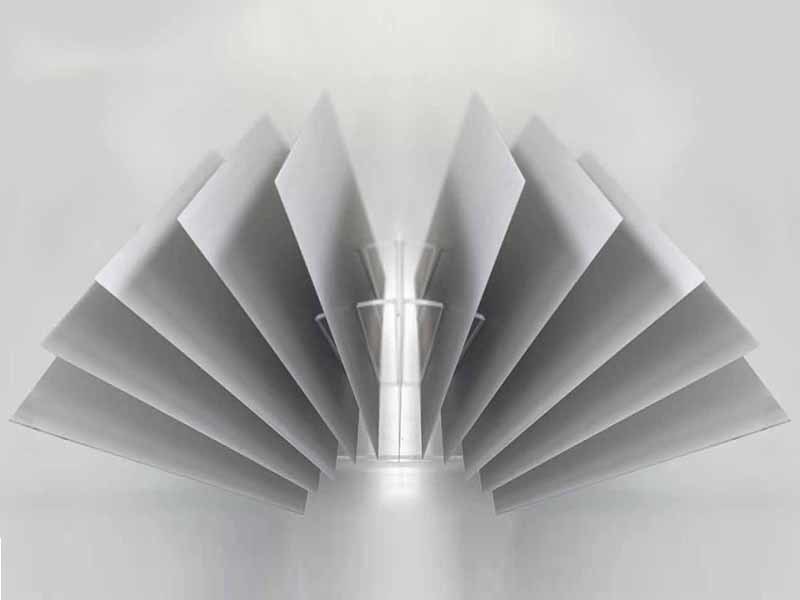

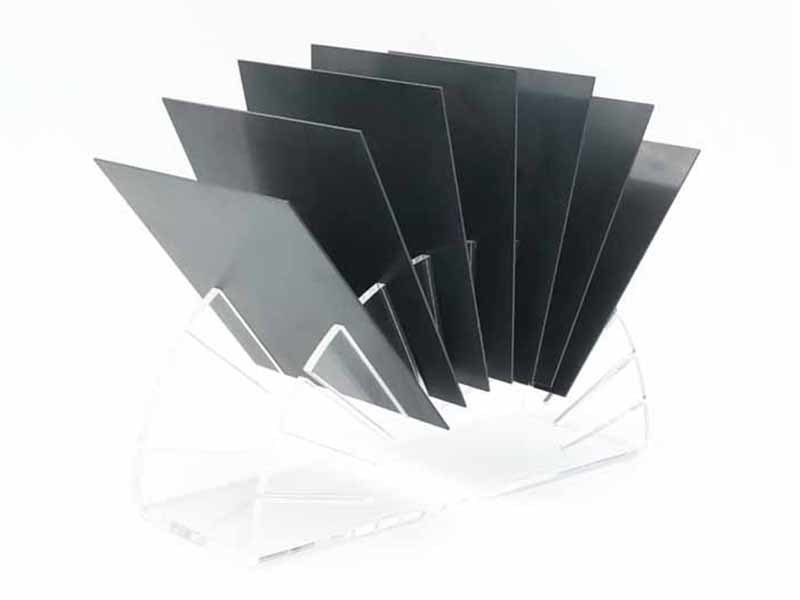

Ceramic Substrates

-

High Thermal Conductivity Silicon Nitride Ceramic Substrates

Silicon nitride ceramic material, with special formula and process, each substrate is sintered at 2000°C, thermal conductivity>80W/(m*k), has passed the quality test of international head enterprises, the size is customized according to customer needs.

-

High Thermal Conductivity Silicon Nitride Ceramic Substrates

Silicon nitride ceramic material, with special formula and process, each substrate is sintered at 2000°C, thermal conductivity>80W/(m*k), has passed the quality test of international head enterprises, the size is customized according to customer needs.

-

High Thermal Conductivity Silicon Nitride Ceramic Substrates

Silicon nitride ceramic material, with special formula and process, each substrate is sintered at 2000°C, thermal conductivity>80W/(m*k), has passed the quality test of international head enterprises, the size is customized according to customer needs.

-

High Thermal Conductivity Silicon Nitride Ceramic Substrates

Silicon nitride ceramic material, with special formula and process, each substrate is sintered at 2000°C, thermal conductivity>80W/(m*k), has passed the quality test of international head enterprises, the size is customized according to customer needs.

Rolling Element

-

Silicon Nitride Ceramic Balls

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings of about 1mm; insulated bearings for new energy automobile motors and machine tool spindle bearings of about 10mm; and insulated bearings for wind power generation of about 50.8mm.

-

Silicon Nitride Ceramic Roller

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings of about 1mm; insulated bearings for new energy automobile motors and machine tool spindle bearings of about 10mm; and insulated bearings for wind power generation of about 50.8mm.

-

Silicon Nitride Ceramic Balls

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings around 1mm; insulated bearings for new energy automobile motors and spindle bearings for machine tools around 10mm; insulated bearings for wind power generation around 50.8mm, etc.

-

Silicon Nitride Ceramic Balls

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings around 1mm; insulated bearings for new energy automobile motors and spindle bearings for machine tools around 10mm; insulated bearings for wind power generation around 50.8mm, etc.

-

Silicon Nitride Ceramic Balls

The sizes range from 0.8mm to 110mm, and the application areas include dental drill bearings around 1mm; insulated bearings for new energy automobile motors and spindle bearings for machine tools around 10mm; insulated bearings for wind power generation around 50.8mm, etc.

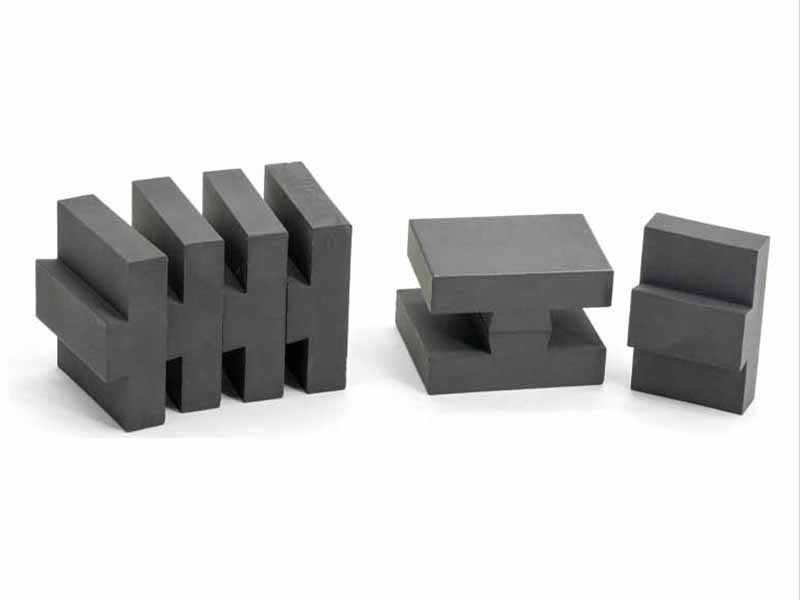

Structural Member

-

Silicon Nitride Ceramic Structures

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Silicon Nitride Ceramic Structural Parts

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

-

Thermocouple Protection Tubes

Products include: low-pressure cast aluminum liquid lift tubes and heater protection tubes, thermocouple protection tubes, high-speed pulp vacuum dewatering tablets, silicon nitride composite insulating ring assemblies, wear-resistant ceramic nozzles, high-pressure ceramic plungers, and so on.

Ceramic Bearings / Hybrid Ceramic Bearings

-

Ceramic Bearings

Application areas of ceramic bearings/hybrid ceramic bearings include: new energy vehicles, electroplating equipment, cleaning machinery, medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, etc.

-

Ceramic Bearings

Application areas of ceramic bearings/hybrid ceramic bearings include: new energy vehicles, electroplating equipment, cleaning machinery, medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, etc.

-

Ceramic Bearings

Application areas of ceramic bearings/hybrid ceramic bearings include: new energy vehicles, electroplating equipment, cleaning machinery, medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, etc.

-

Ceramic Bearings

Application areas of ceramic bearings/hybrid ceramic bearings include: new energy vehicles, electroplating equipment, cleaning machinery, medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, etc.

-

Ceramic Bearings

Application areas of ceramic bearings/hybrid ceramic bearings include: new energy vehicles, electroplating equipment, cleaning machinery, medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, etc.